Injection moulding is a powerful manufacturing process capable of producing intricate and high-quality parts at scale, for a range of different industries and uses. However, to leverage its full potential, careful attention must be paid to various design considerations.

In this article, we will explore key considerations for injection moulding, offering insights into how to optimise the process for the best possible outcomes and ensure the production of robust, functional, and aesthetically pleasing components while maintaining cost efficiency.

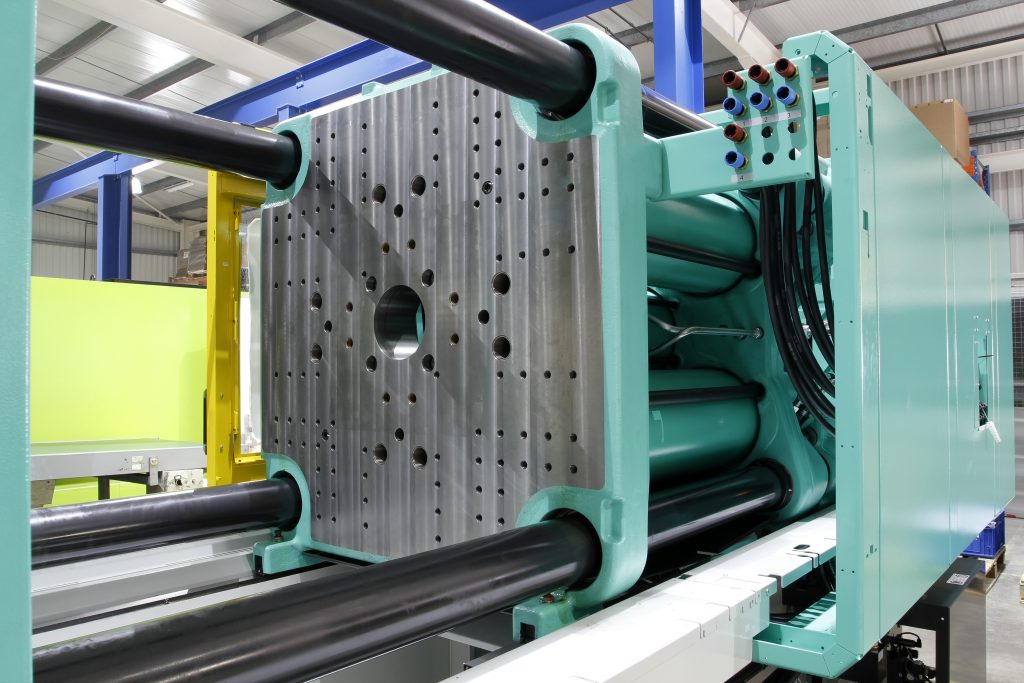

Key Design Considerations for Injection Moulding

Material Selection

The choice of material is crucial in injection moulding as different materials have varying properties such as melting temperature, flow characteristics, and strength. The selected material must be compatible with the product’s intended use and moulding process.

Part Design

The design of the part being moulded influences the result of the injection moulding process. Key aspects to consider include:

- Wall thickness

- Draft angles

- Ribs and bosses

Mould Design

- Cooling channels: Efficient cooling is necessary to minimise cycle times and improve the quality of the moulded part.

- Gate location and type: The location and type of gate (the entry point of the molten material into the mould) affect the flow of material and the quality of the final product. Gates should be placed to ensure uniform material flow and minimise defects.

- Ventilation: Adequate ventilation is necessary to allow air to escape from the mould cavity, preventing voids and incomplete fills.

Tolerance and Precision

Injection moulding can produce high-precision parts, but this requires careful attention to tolerances. Tight tolerances may necessitate higher mould costs and more precise control over the moulding process. Designers should balance the need for precision with cost considerations to optimise the production process.

Surface finish and texture

The surface finish of the mould affects the appearance. These elements can affect everything from the product’s appearance and feel to its durability and ease of use.

Why Design Considerations are Important for Injection Moulding

Design considerations are crucial for injection moulding as they directly impact the quality, functionality, sustainability, efficiency, and cost-effectiveness of the final product. Proper design ensures dimensional accuracy, a smooth surface finish, and structural integrity, enhancing the product’s performance and usability. It also improves manufacturing efficiency by reducing cycle times and defects, while lowering costs through material efficiency and extended mould lifespan.

Injection Moulding Services across the UK

With 20-plus years in the injection moulding world, Pro-Moulds take pride in manufacturing moulds to the best of their ability.

Pro Moulds provides toolmaking, tool repair, laser welding and injection moulding services. Through offering an extensive line of equipment, the teams have worked with a wide range of industries, helping businesses and communities meet their visions.

If you would like to talk about your injection moulding needs then please call us on 01623 904 417 and a member of our technical team will be happy to help. Alternatively, you can email us using our contact page.